Wireform Components

Engineering Precision

Delivering Global Trust

From concept to creation, Wireform Components powers the world's most trusted brands

Serving Diverse Industries

Our manufacturing expertise supports multiple global industries, with a balanced portfolio that reflects adaptability, scale, and long-term partnerships.

Toys

Electrical, Electronics & Automotive Components

Pipes & Fitting Accessories

End-to-End Manufacturing Capability

From idea to performance, our diverse capabilities span tooling, engineering, manufacturing, and quality—ensuring we meet the unique requirements of every global client.

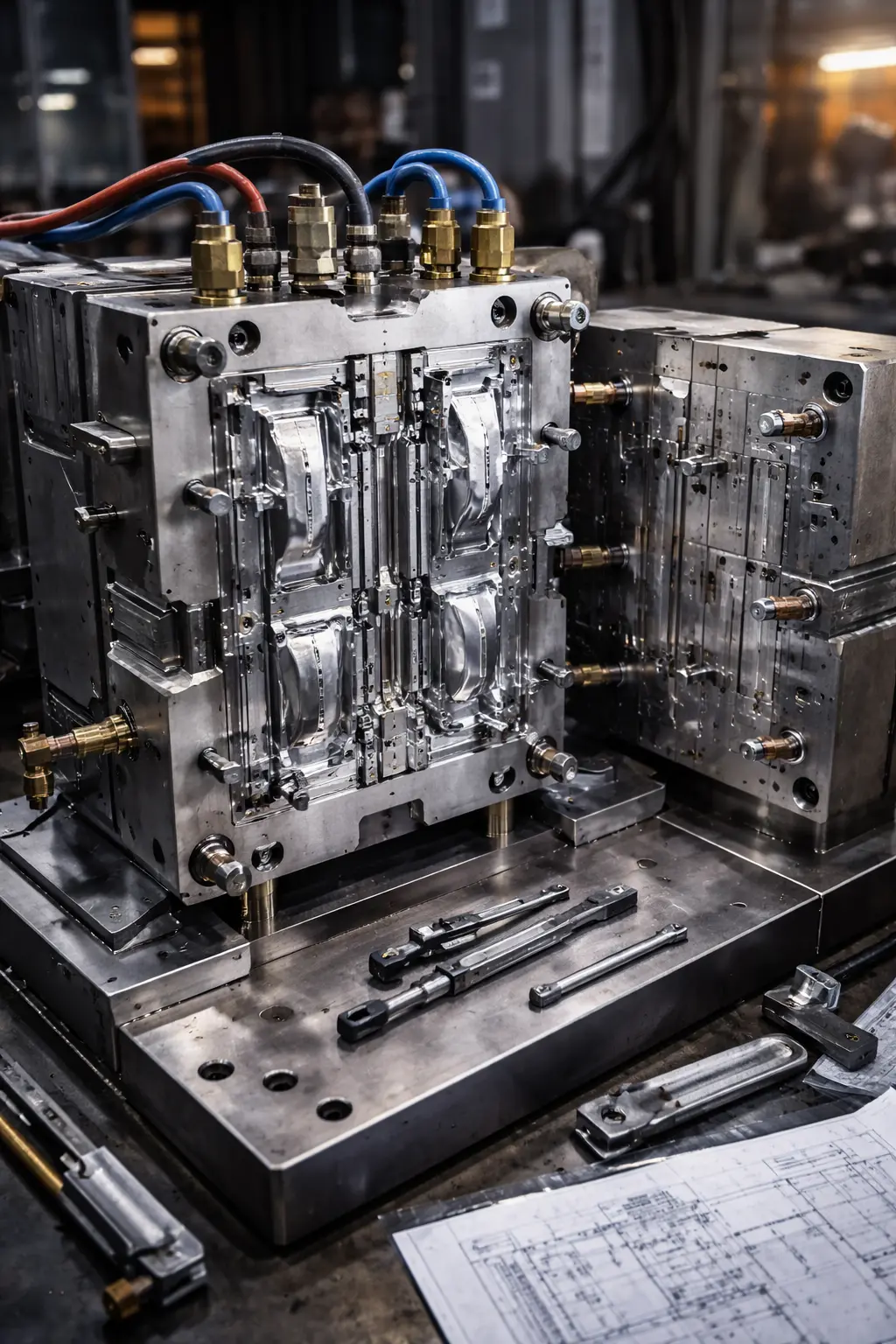

Rapid Delivery

We engineer speed without compromise.

From concept to finished mold, our advanced tool room delivers fully validated, production-ready molds within 10–15 days, enabling faster product launches, reduced downtime, and a decisive competitive edge for global customers.

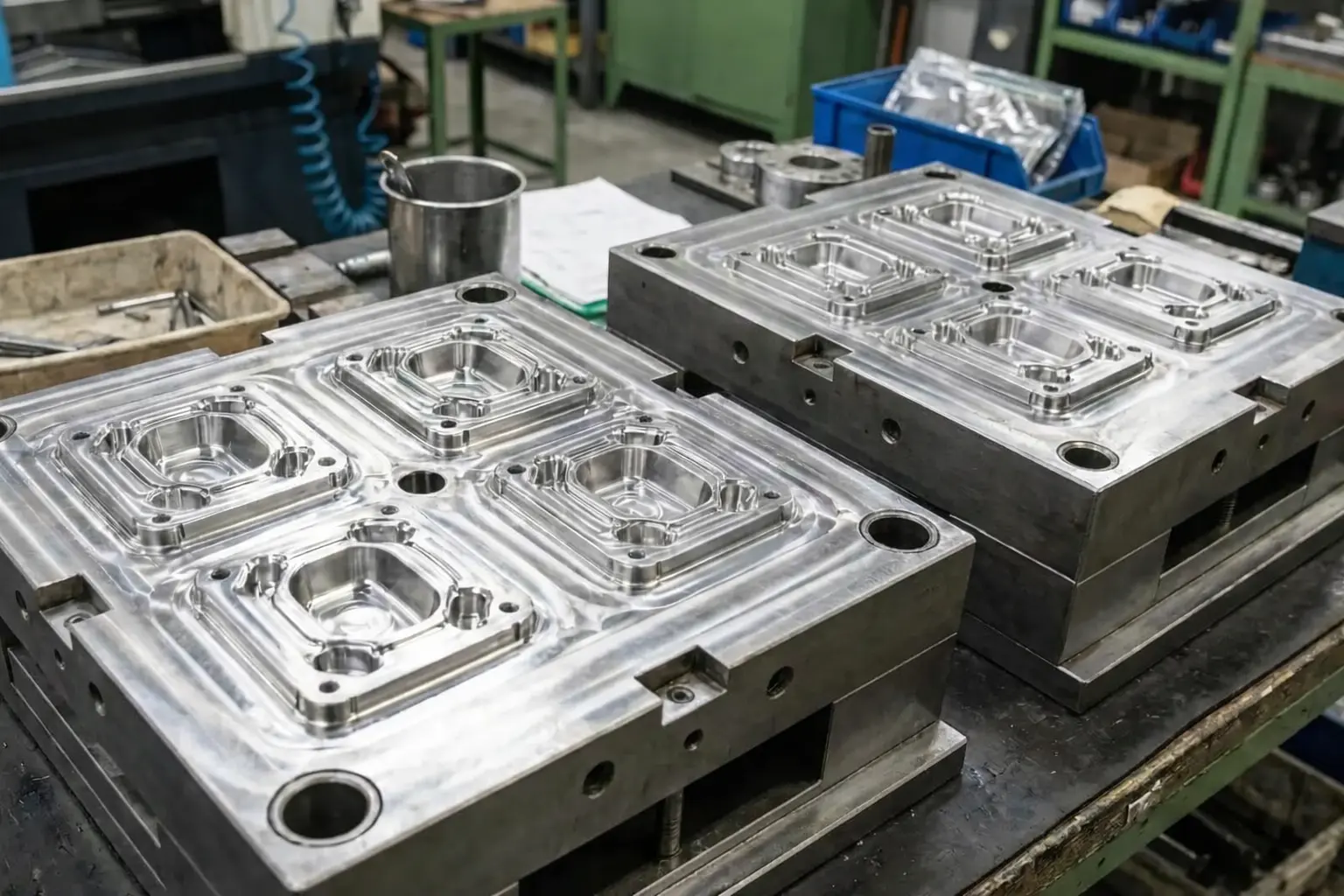

Multi-Cavity Molds

Designed for scale, consistency, and long-term performance.

Our multi-cavity molds are precision-engineered to ensure uniform output, tight dimensional control, optimized cycle times, and repeatable quality, making them ideal for high-volume manufacturing across automotive, toys, and consumer applications.

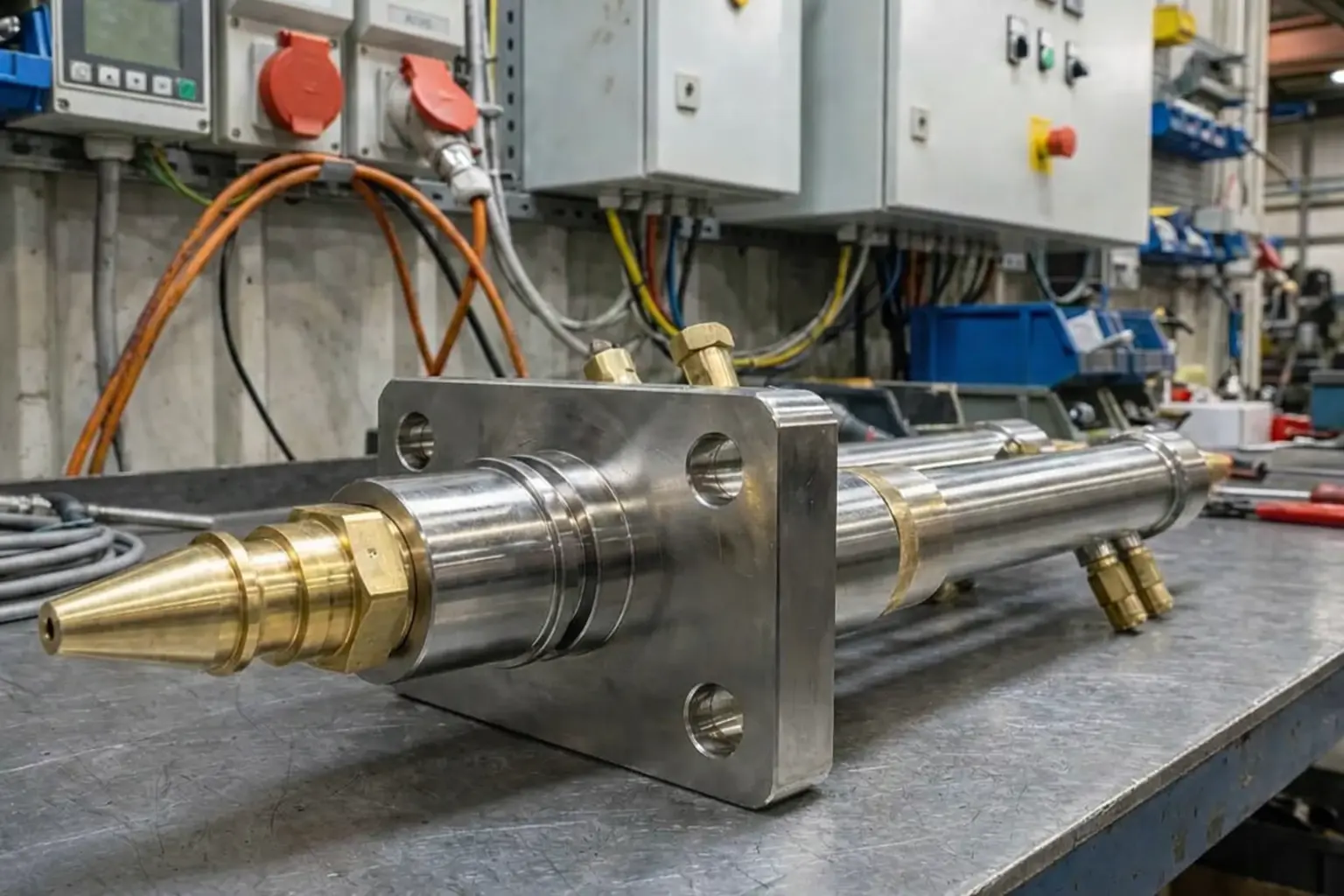

Hot Runner Systems

Engineered for efficiency at every shot.

Our hot-runner mold solutions minimize material waste, enhance surface finish, and ensure consistent melt flow, delivering superior part quality, reduced cycle times, and cost-efficient production for complex, high-performance components.

Over-Molding

Where materials merge to create performance.

We specialize in advanced over-molding solutions that seamlessly combine multiple materials into a single component, enhancing strength, functionality, and aesthetics while meeting demanding application requirements across automotive, appliances, and consumer products.

VMC & EDM Machining

Precision built at the micron level.

Equipped with world-class VMCs and EDM machines, our tool room achieves exceptional accuracy, intricate detailing, and tight tolerances, enabling us to manufacture complex tooling that performs flawlessly across high-pressure, high-volume production environments.

Engineered Product Excellence

Discover a versatile product portfolio that blends proprietary innovation with custom precision. We offer a wide range of high-performance solutions engineered strictly to client specifications, alongside select self-developed products protected by our intellectual property.

A Journey of Engineering Excellence

From a single manufacturing unit to a globally trusted precision partner, our journey reflects continuous growth, innovation, and commitment to quality.

Established Plant One, marking the foundation of a long-term manufacturing vision

Launched over 50 houseware products, building a strong presence in consumer manufacturing

Entered the automotive manufacturing sector, meeting stringent quality and performance standards

Grew into a 100+ expert-trained team, strengthening skill, scale, and operational excellence

Inaugurated Plant Two, a world-class facility designed for advanced, scalable manufacturing

Expanded into global contract manufacturing, delivering high-quality toys for leading customers in the USA and UK

Launched advanced metal stamping and precision tooling capabilities, enabling tighter tolerances and complex part production

Scaled up Injection Molding and Tool Room operations, strengthening in-house design, tooling, and manufacturing control

Engineering a Greener Tomorrow

At Wireform Components, we prioritize operational efficiency to decouple growth from emissions. Our data-driven approach ensures a measurable reduction in our environmental footprint.

Decarbonization

Reducing carbon intensity through energy-efficient CNC and precision molding.

Circular Economy

Closed-loop manufacturing focusing on resource recovery and zero-waste goals.

Eco-Innovation

Pioneering bio-resins and low-impact polymers in precision molding.

Ethical Sourcing

Upholding global ESG transparency and strict environmental laws.

Reduction in Emission Intensity (per unit of sales) from 2019 to 2024.

Our Global Customers

We are proud to partner with leading global brands across industries, delivering precision-engineered components.

Compliance & Certifications

Our operations are governed by internationally recognized standards, ensuring quality, safety, sustainability, and ethical manufacturing across every product we deliver.

Talking to Us Is Easy

Whether you’re exploring a new project, need technical clarity, or want to discuss long-term collaboration, our team is just one conversation away.

Email us at

support@wireformindia.com