Electrical & Electronics Parts

Wireform Components designs and manufactures high-precision electrical and electronic parts that form the backbone of modern power, signal, and control systems. Our components are engineered to meet exacting dimensional, electrical, and mechanical requirements demanded by industrial, automotive, and energy applications.

Backed by advanced manufacturing processes, robust quality systems, and deep application expertise, we support both high-volume production and complex custom programs. Every part is built to perform reliably under stringent electrical, thermal, and environmental conditions — ensuring long-term durability, safety, and consistent field performance.

What We Manufacture

We manufacture a wide range of precision electrical and electronic components that support power distribution, signal transmission, grounding, and mechanical retention in critical assemblies. Our portfolio includes both standard and application-specific parts produced to tight dimensional and functional tolerances.

Leveraging advanced forming, machining, and finishing processes, we deliver components optimized for electrical performance, mechanical strength, and long-term reliability. Our manufacturing capabilities scale seamlessly from prototyping and validation builds to high-volume serial production, ensuring consistency, traceability, and repeatability across programs.

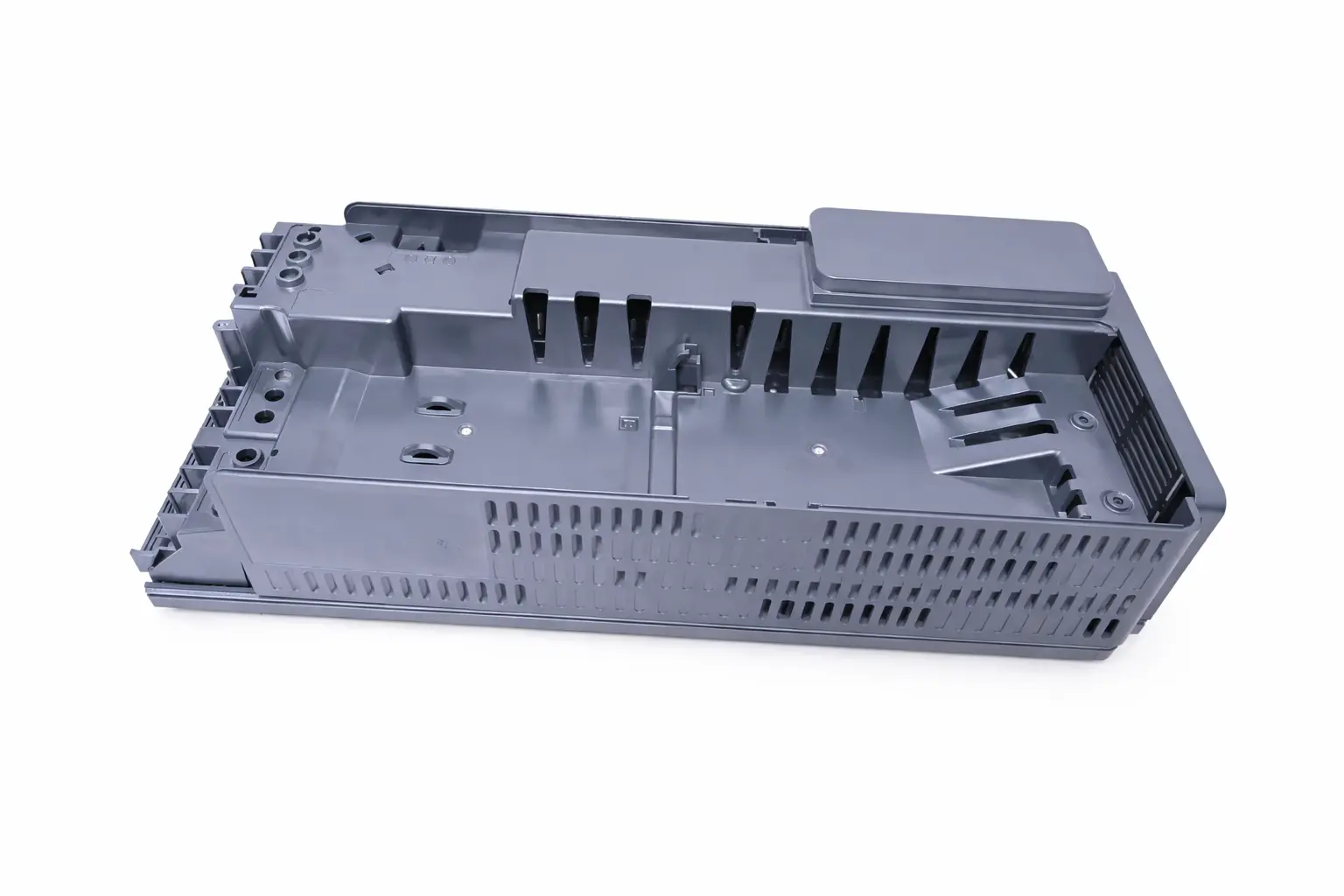

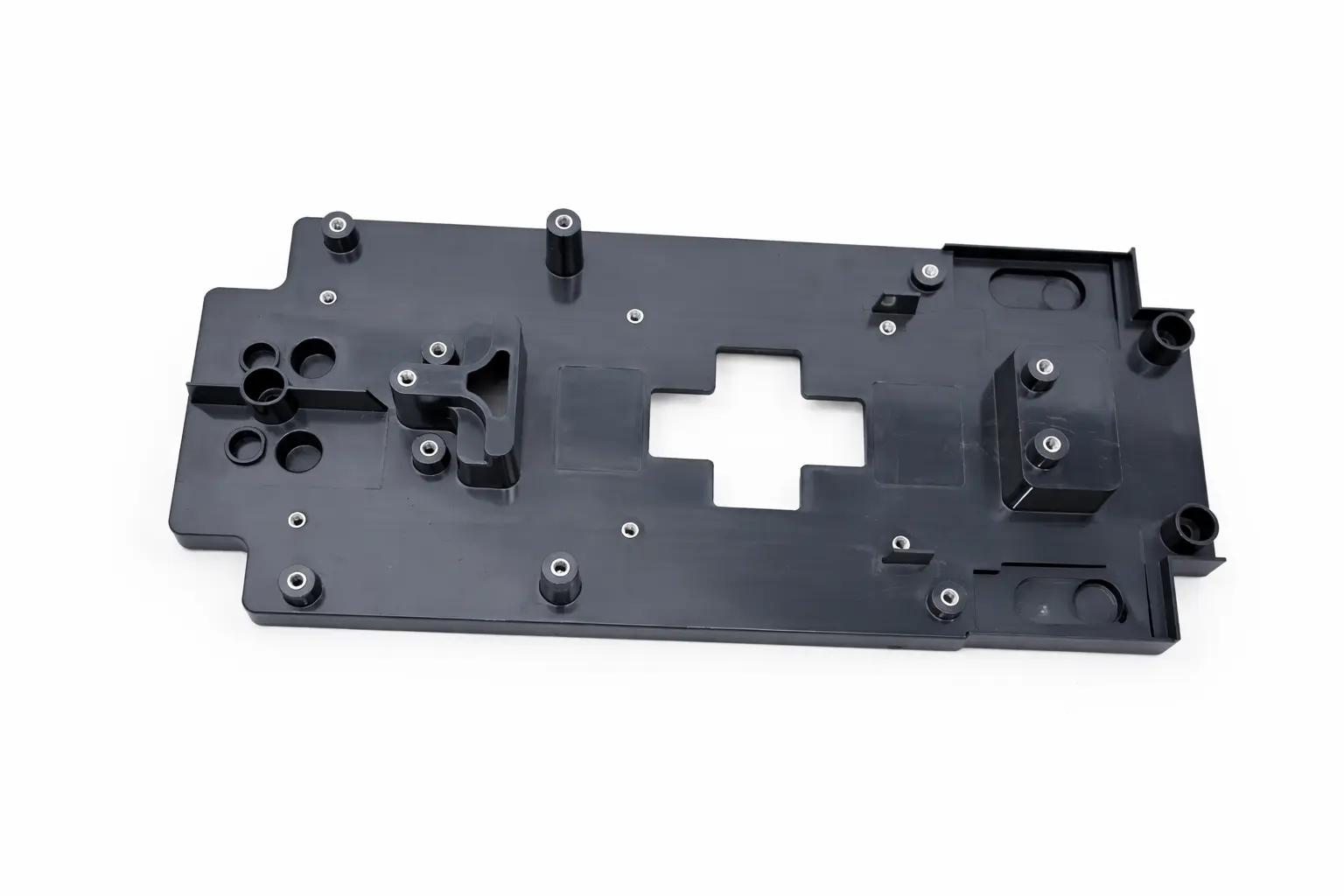

Product Gallery

Our Global Customers

We are proud to partner with leading global brands across industries, delivering precision-engineered components.

Quality & Compliance

Quality and compliance are embedded into every stage of our manufacturing process, from raw material selection to final inspection and dispatch. Our quality management systems are structured to meet stringent OEM and Tier-1 supplier requirements, ensuring consistent conformance, traceability, and process control.

All electrical and electronic components are manufactured under controlled processes supported by defined inspection plans, in-process monitoring, and validated measurement systems. Critical characteristics are closely monitored to ensure electrical integrity, dimensional accuracy, and functional reliability across production volumes.

Our quality framework emphasizes preventive controls, root cause analysis, and continuous improvement to minimize variation and eliminate defects. Comprehensive documentation, lot traceability, and change management practices support reliable deliveries and long-term performance in demanding electrical, industrial, and automotive applications.