Wireforming & Multislide

Wireform Components specializes in precision wireforming and multislide manufacturing, producing complex metal components with tight tolerances and consistent repeatability. Our capabilities enable the efficient production of high-strength, dimensionally accurate parts for automotive, industrial, consumer, and appliance applications.

By combining advanced multislide technology with robust tooling and process control, we deliver cost-effective solutions for both simple and highly intricate wireforms. Our manufacturing approach supports high-volume production while maintaining superior form accuracy, mechanical performance, and long-term durability.

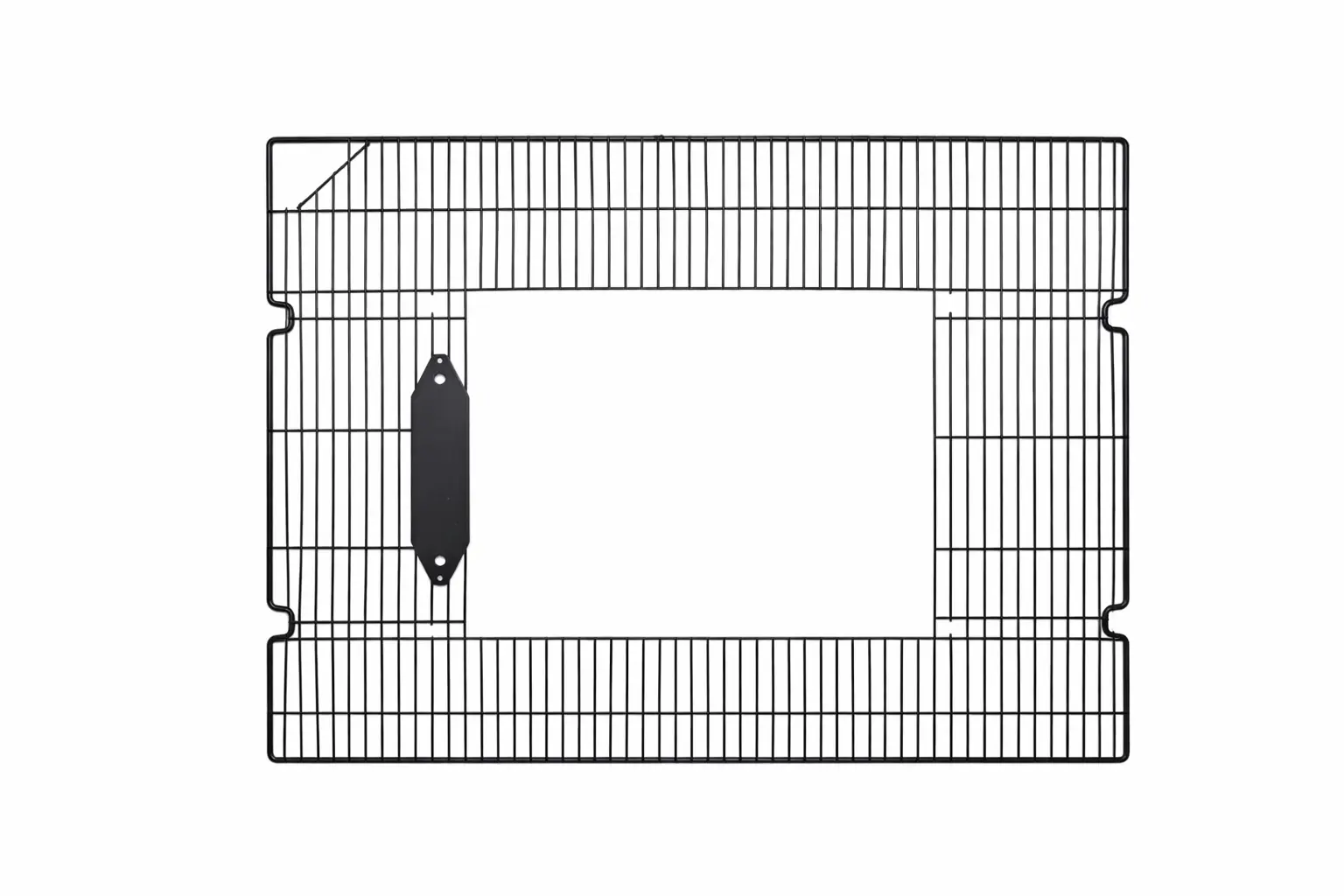

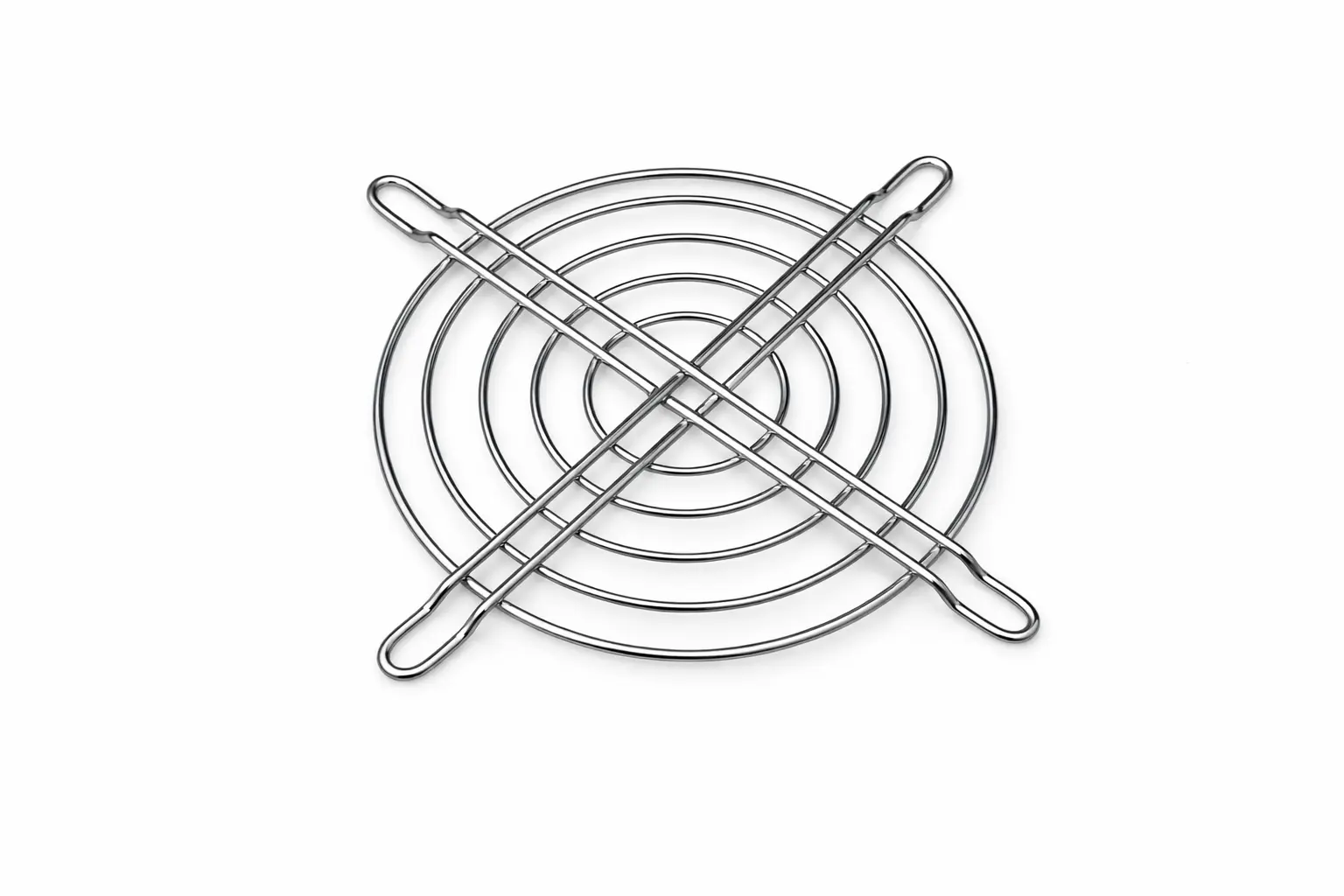

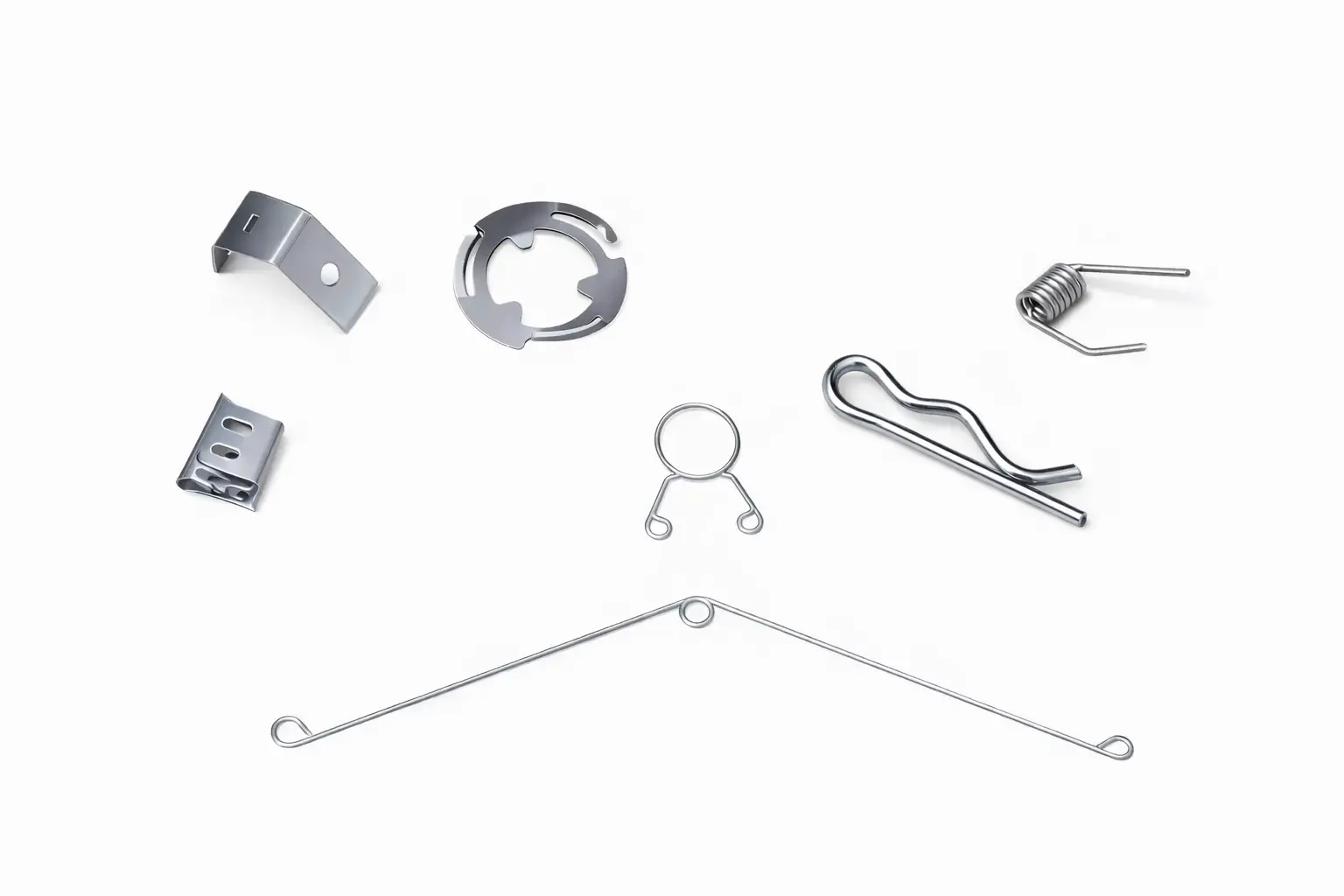

What We Manufacture

We manufacture a wide range of precision wireformed and multislide components, including clips, springs, brackets, retainers, frames, and custom bent-wire parts. Our components are designed to meet specific functional, mechanical, and dimensional requirements across diverse applications.

Using multi-axis forming, progressive tooling, and secondary operations, we produce parts with complex geometries, tight tolerances, and high structural integrity. Our capabilities support rapid prototyping, validation builds, and scalable high-volume production with consistent quality and repeatability.

Product Gallery

Quality & Compliance

Quality and compliance are integral to our wireforming and multislide manufacturing operations. Our quality management systems are structured to ensure consistent process control, dimensional accuracy, and conformance to customer and regulatory requirements across all production programs.

All wireformed and multislide components are manufactured under controlled processes supported by defined inspection plans, in-process monitoring, and validated measurement systems. Critical dimensions and functional characteristics are closely monitored to ensure repeatability and mechanical reliability.

Our quality framework emphasizes preventive controls, traceability, and continuous improvement through root cause analysis and corrective actions. This disciplined approach supports zero-defect delivery, stable production, and long-term performance in demanding automotive, industrial, and consumer applications.